Repair cracks

Repair of cracks in concrete

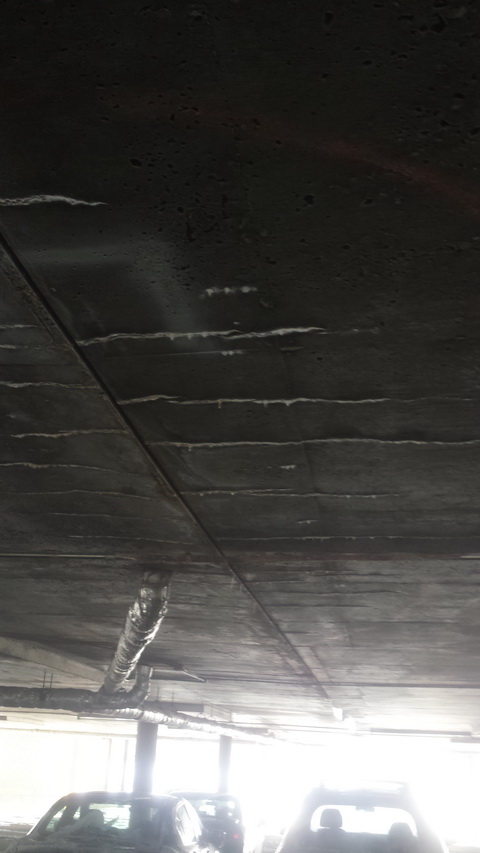

Cracks that are not repaired can grow if they are not repaired as soon as possible.

Repair of cracks in your foundation even during water infiltration!

Types of crack repair:

- Epoxy application on the crack

- Injection at high pressure or low pressure into the crack using polyurethane or epoxy.

- Injection of cementitious grout into the crack

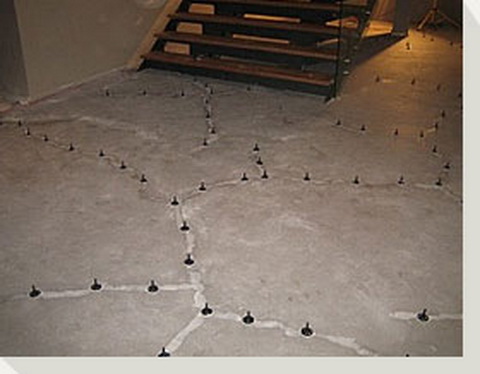

Crack repair step:

- Drill holes in the crack every 4 to 6 inches to inject the appropriate product as efficiently as possible

- Clean holes and cracks

- Installation of injectors in the crack

- Inject the polyurethane at a pressure of 3000 lbs to 10000 lbs in order to seal the crack

Our company is at the forefront of technology around the world, we inject cracks under pressure using a specialized injector.

We inject flexible polyurethane to ensure our repair (injection) if the ground is in motion.

All our products are approved by the MTQ hydro Quebec and the airports for a satisfaction ensure.

Cracks can be sealed even during infiltration.

Epoxy injection can also be done if necessary when the crack is too large we can also install inking units on the crack to stabilize it.

Crack in a foundation due to ground movement

Which anchor to choose for your foundation?

RHINO CARBON FIBER from CONCRETE CRACK LOCK® CONCRETE

Rhino Carbon Fiber ™ Concrete Crack LockStitches ® are a concrete crack bridging/stitching solution that repairs and strengthens cracks in concrete, increasing integrity. Carbon Fiber, developed to take full advantage of the tensile strength of carbon fiber, reduces labor time and costs while providing a more aesthetic finished appearance (can easily be painted or coated with a finishing product). Carbon fiber is lightweight, easy to install, durable (10 times stronger than steel) and non-corrosive, eliminating the need for maintenance. Rhino Carbon Fiber ™ Concrete Crack Lock® are ideal for concrete slabs, poured walls, masonry, columns, industrial buildings, bridges, roads, swimming pools and hundreds of other residential and commercial applications.

There are a variety of products available for bridging / stitching cracks in concrete, however, Rhino Carbon Fiber ™ Concrete Crack Lock The Stitches® are revolutionary, designed to make crack reinforcement more efficient, cost-effective, and less labor intensive than the competition.